Our goal is to give our customers the best for quality & price and provide unparalleled service and support on an ongoing basis. We strongly believe that the benefits of cost saving thru innovative practices must translate into maximizing profits for the customer. We do this by creating and replicating best business practices aimed at reducing the total cost of ownership.

We want to achieve a market leadership position because our vision is inspired from greatness and we want our customers to feel both proud and rewarded by associating with us .We help our customers grow by creating winning strategies of procuring high quality material at hard to beat prices and lifting the heartache off the customers shoulders by utilizing reliable and time tested strategies of supply chain management. The company envisages itself becoming a worldwide leader in its field of operations by consistently delivering world class products in the lowest possible lead times at the most competitive rates.

Why Us

Because we have,

• Consistency and cost effectiveness.

• A yearn of specialization and total commitment to quality.

• Unrelenting thrust towards continuous quality improvement.

• Customer based culture with clear accountability and strong performance managements.

• A blend of experience and technical expertise that is unsurpassed.

Products

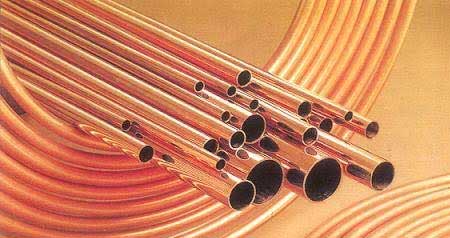

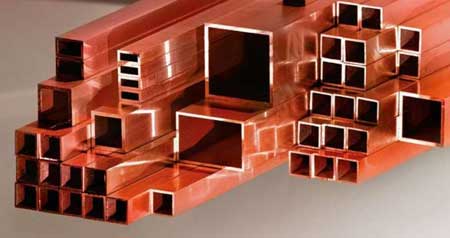

Our product range includes a complete assortment of copper tubes and copper alloy tube products meant to satisfy the most discerning Customers. We manufacture Copper Tubes, Copper Coils, PVC Coated Copper Tubes, Square Copper Tubes, Rectangular Copper Tubes, Hexagonal Copper Tubes, Special Profile Copper Tubes, All types of Copper Flanges & Copper tubes with end forming such as - beaded copper tubes, copper tubes with expanded ends, Copper Tubes with reduced ends, Copper tubes with flanged ends, Copper Pipe Bends, Copper Piping Systems, Copper U Tubes & copper fittings - Tailored to Customer's specific requirements.

Infrastructure

Tube Tech Copper And Alloys Pvt. Ltd. is technically and professionally well equipped to manufacture high performance and defect free copper and copper alloy tubes. We are situated about 100 kms North of Mumbai at Palghar in Thane District and have a state-of-the-art Manufacturing plant - staffed with skilled resources and backed by stringent Quality procedures to satisfy the most diverse and the most discerning Client's needs.

To meet the global challenges of quality and performance, our production unit is adequately equipped with hi-tech modern tools and updated technology. This empowers us to provide our clients a competitive edge over others and create value for the firm. We have been constantly upgrading our infrastructure to meet the dynamic demands of the industry. Ongoing substantial investment programs are testament to our commitment to excellence in the product quality and Customer service.

Manufacturing Process

Mother Tubes are procured from reputed manufacturers and are subjected to a thorough chemical analysis along with rigorous physical and mechanical tests. The best quality mother tubes are then cold drawn on the draw benches.

Drawing involves pulling the hollow tube through a series of tungsten carbide dies of gradually decreasing diameters. Before each step of the drawing process, the tube is pointed at one end to fit through the next smaller die. Before drawing a stationery tapered plug mandrel is placed inside the tube. As the tube is drawn on linear draw benches, the mandrel and die act together to reduce both the tubes outside diameter and its wall thickness. The mandrel also makes the tubes inside surface smoother.

The tube is annealed in an annealing furnace as and when required by the given standard to make it suitable for the intended application. The straight tubes are passed through a series of straightening rolls before the final cutting operation to make it perfectly cut to the size. The soft annealed coils are wounded on the automated coilers.

Finally, the tube is cleaned to remove any traces of drawing lubricants or other contaminations. Samples of the finished tubes are analyzed at regular intervals to ensure that it meets all requirements of size, wall thickness and quality as required under the applicable standards.